Standard square shaft helical piles are usually mounted using compact equipment such as a skid-steer loading machine or an excavator, equipped with hydraulic drive heads. This method not only allows for faster installation but also eliminates the need for extensive ground preparation.

One of the main elements of helical pile installation is achieving the desired load capacity. This is when the relationship between the installation tension and capacity is crucial. The most modern torque gauges, such as those from Chance Digital Torque Indicator, are a key component in this process, providing accurate measurements, and removing the uncertainty associated with hydraulic pressure estimations.

The speed at which the installation takes place is vital, generally ranges between 8 to 16 RPM. This controlled speed will ensure that the pile moves approximately three inches each revolution which is in line with the pitch of the helical plates. If the pile does not move in the manner expected, adjustments such as the increase of downward thrust or the addition of larger plates for helicals are made to prevent spinning out like the threads of a screw being stripped.

A firm foundation when the ground is shaky University of Nevada, Reno

Posted by on 2021-01-27

Heerema Marine Contractors Develops Concepts for Silent Foundations Society of Petroleum Engineers

Posted by on 2021-01-27

Federal Circuit Affirms District Court Claim Construction in Foundation Pile Patent Infringement Dispute IPWatchdog.com

Posted by on 2020-09-04

Construction is Underway on the Davis Road Boardwalk – The Bedford Citizen The Bedford Citizen

Posted by on 2020-01-10

Helical piles are also excellent in sustainability, a key concern in the modern day construction methods. Since they cause minimal disturbance to the land and do not require concrete, their environmental impact is much less than traditional foundations. Furthermore, they are typically constructed of recycled steel and their removable nature allows them to be reused, increasing their eco-friendly appeal.

Another benefit of helical piles is their capacity to be load-bearing right after installation. This immediate load transfer capability lets construction proceed without a delay, which is in stark contrast to the time-consuming waiting times that are associated with concrete foundations. It also provides a distinct advantage in emergencies or in the case of unstable structures which require immediate stabilization.

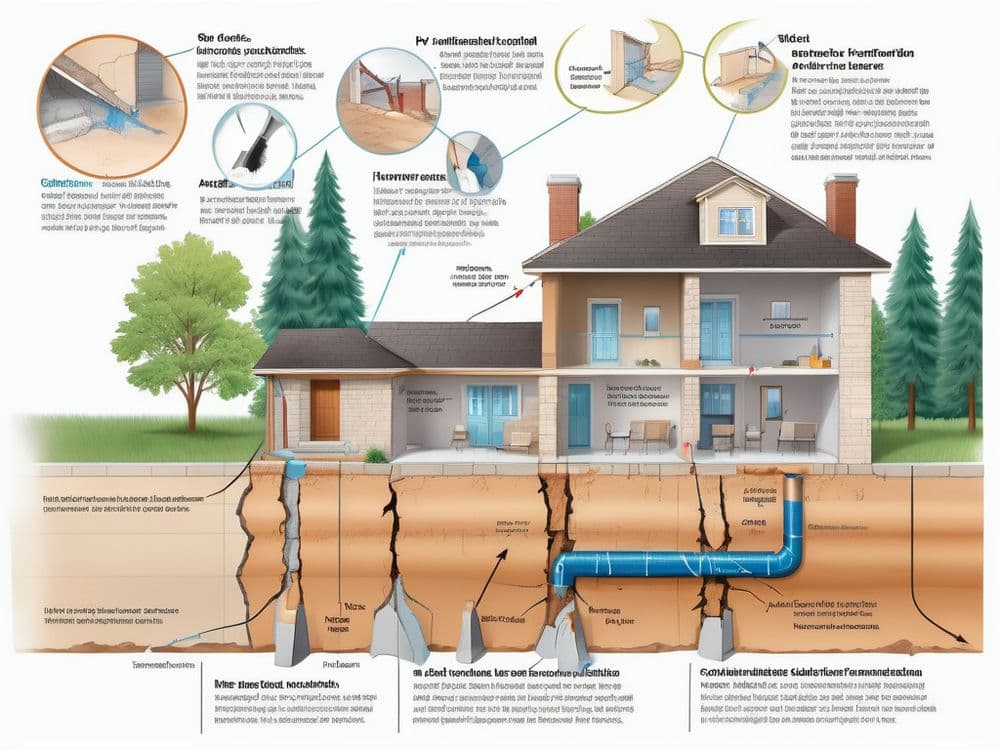

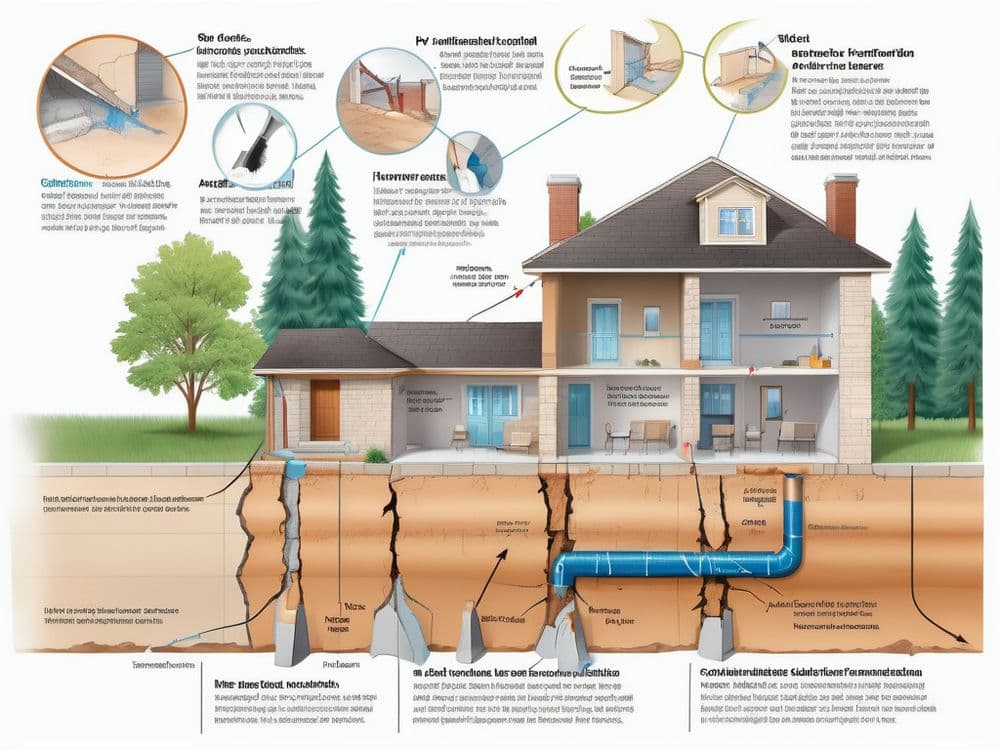

Helical piles also referred by the name of screw piles are one type of deep foundation system consisting from a shaft central that has one or more blades that resemble helix shapes. The design permits the screw to be inserted into the ground, creating solid and secure foundation for different types of structures. Originating from the 19th-century innovations from Irish engineer Alexander Mitchell, helical piles have evolved and are now at the forefront of modern foundation technology.

One of the most notable advantages of helical piles are their ease and speed of installation. Unlike traditional concrete foundations, that require a significant amount of excavation and curing time, helical piles can be quickly installed using hydraulic equipment. This does not just speed up the process of construction but also reduces their impact on environmental. The less need for huge excavations makes them especially advantageous in urban settings or in areas with environmental concerns where the preservation of natural landscapes is essential.

Alongside their main advantages, helical piles come with a range of additional advantages that strengthen their place in modern construction. They include:

These additional features, coupled with their primary advantages they make helical piles a highly versatile and effective foundation choice for a range of construction projects.

Speed of construction is one of the biggest benefits of helical piles. In contrast to conventional foundations which require long excavation and curing they can be put in place quickly and often in just hours. This efficiency not only saves time but also cuts down on the cost of labor which makes the projects more affordable.

A further advantage of helical piles is their comparatively low environmental impact. Their process of installation is more secluded, which results in lesser soil disturbance. This feature is particularly beneficial in sensitive ecological areas or in urban settings where preserving the integrity of the surrounding environment is crucial.

Based on the strength and foundation of the helical piles Their usage in construction projects provides several advantages. These are in the following manner:

These factors highlight the many benefits of the use of the helical piles in highlighting their role in improving efficiency, sustainability and cost-effectiveness of construction.